featured

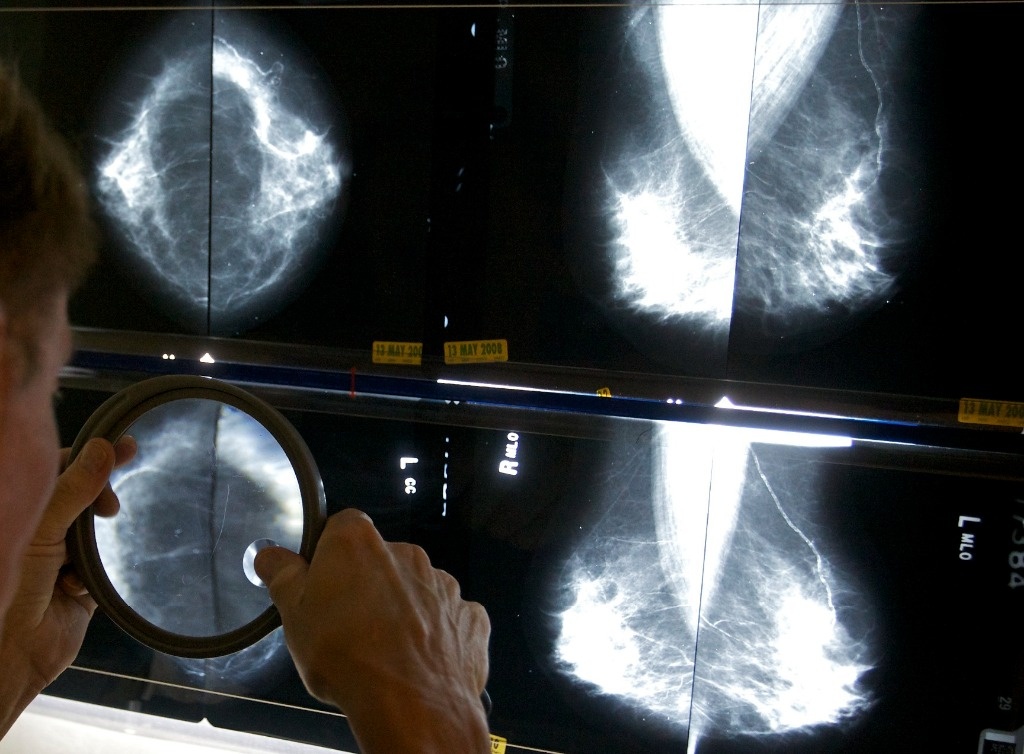

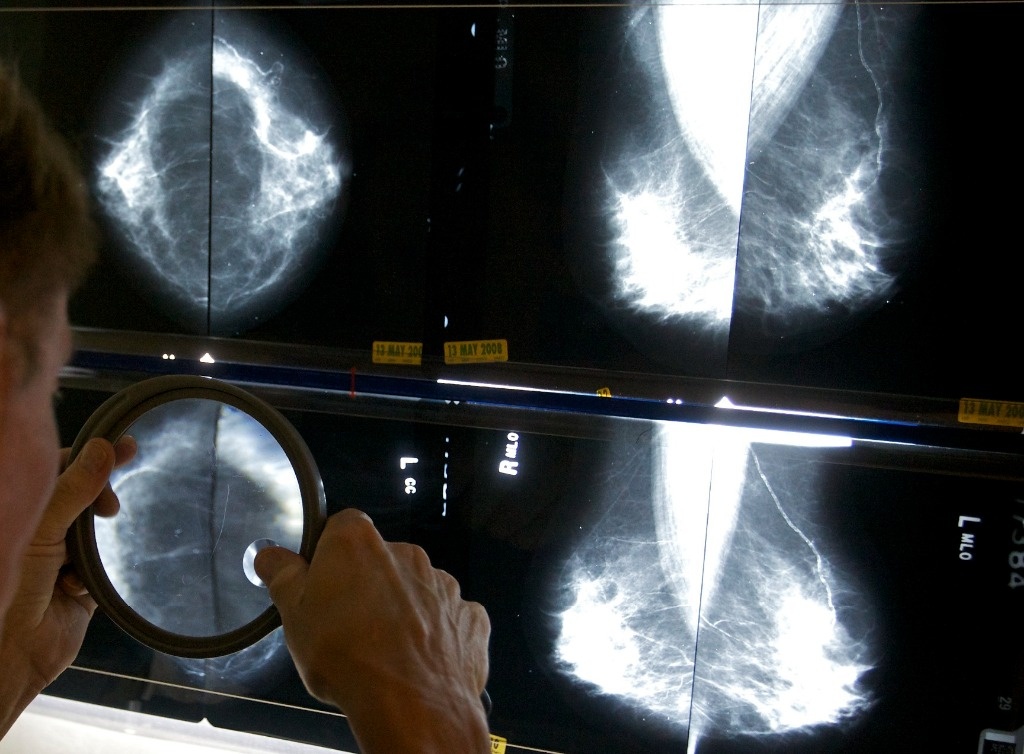

They recommend mammograms in the US from the age of 40

Washington. Women should start having mammograms every 24 months starting at age 40 to reduce the risk of dying from this disease, the United States Preventive Services Task Force recommended this Tuesday. Until now, this …

They recommend mammograms in the US from the age of 40

Washington. Women should start having mammograms every 24 months starting at age 40 to reduce the risk of … Read more

Car crash in Mojokerto graveyard caused by driver learning to drive – Latest News

Jakarta – An Innova car crashed into a graveyard in Lolawang Village, Ngoro, Mojokerto. The accident was caused … Read more

US Secretary of State Visits Gaza Border Crossing for Humanitarian Aid – Blinken Urges Israel to Increase Aid Flow to Gaza

Jakarta – Secretary of State of the United States (US), the, he visited the main Gaza border crossing. … Read more

Ministry of Health Strengthens HPV Vaccination Campaign in Ecuador from May 2 to June 30

From May 2 to June 30, the Ministry of Health will strengthen the vaccination campaign against the Human … Read more