featured

The season was over for Vosselaar and Brasschaat, … but now they are playing the final round: “In fact, everyone wants to continue playing in the interprovincial”

Roos Willemsen (VVC Brasschaat), top scorer in the series. — © RR Women football Vosselaar played the last match of the competition last weekend. The score was 0-1 against Bosdam-Beveren. Number three in Interprovincale B …

The season was over for Vosselaar and Brasschaat, … but now they are playing the final round: “In fact, everyone wants to continue playing in the interprovincial”

Roos Willemsen (VVC Brasschaat), top scorer in the series. — © RR Women football Vosselaar played the last … Read more

From dead chickens to diapers and wood waste in organic waste containers: “We are going to check incorrect sorters more strictly” (Sint-Niklaas)

People have already put vacuum cleaner bags, plastic bags and even a dead chicken in the organic waste … Read more

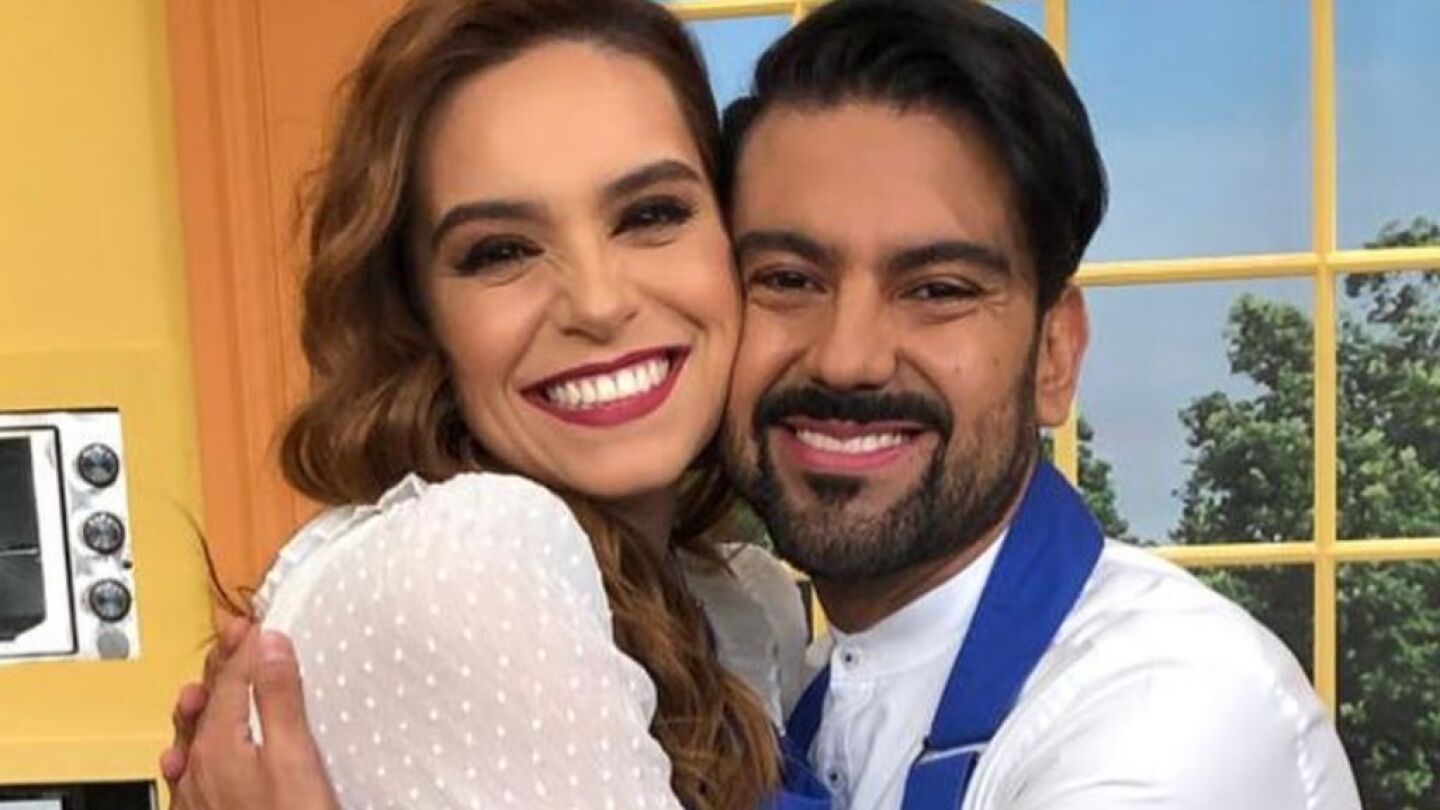

Is chef Mariano Sandoval leaving ‘VLA’? They claim that Tania Rincón is advocating to integrate him into ‘Hoy’!

Mariano Sandoval has stood out as one of the most famous chefs on Mexican television, given that he … Read more

Movistar fell across the country: what happened

If your phone operates under the company Movistar and you have some problems using it, we tell you … Read more

First presidential debate cost 12.7 million pesos: INE

The first presidential debate, held on April 7, cost 12.7 million pesos and was watched by 13.7 million … Read more